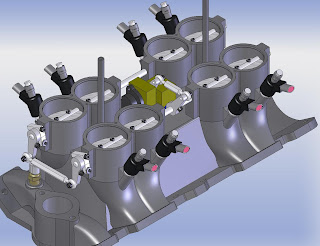

I designed the injection system in Solidworks. It allowed me to be able to have drawings for all of the parts that needed machined and lazer cut. It took me a great deal of time to get everything just right, it is more difficult than if looks. Things can get pretty tight when trying to implement all the EFI components, as well as a scoop. I always try to make each component have more than one purpose as seen in the block in the center of the manifold that contains the TPS and a small manifold block to draw a vacuum signal (the IR intake basically turns the engine into 8 individual cylinders)

(This is the manifold I started with, an old mechanical injection, I do not even know who made this unit for sure.)

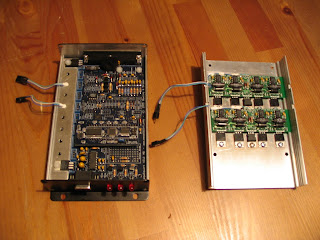

In the conversion, I also needed an EFI controller. These can be a very expensive part of the conversion and a reason that people do not make the switch , so i put one together myself with a processor and board from group of enthusiasts that developed what is called a Megasquirt II . The great part about this is it is very versatile, and inexpensive as you build and configure it yourself as long as you are willing to put the time in and learn a few things. It was basically developed by a bunch of car guys that had a lot of programming, and IC engine knowledge and had some time on there hands. As such, all the software (tuning and data logging) is very inexpensive. The extra box on top is for the Low impedance injector drivers. I am running 120lb/hr low Z injectors on methanol (4A peak.1A hold) on a belt drive pump.

(processor etc on left, Low Z boards on right)

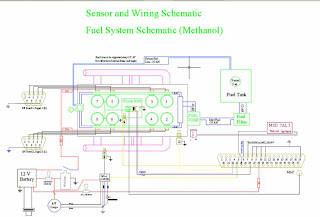

(I had to create a schematic for future troubleshooting)

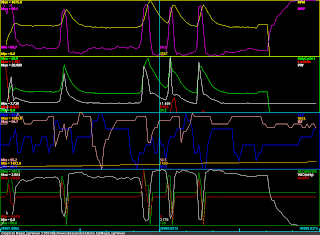

(Data logging during tuning)

I purchased a long block from a guy in Michigan. It has a Dart Little M block, Brodix Track1 heads, Scat Crank, Oliver Rods, Wiesco pistons, 14.5:1 compression, Jesel shaft rockers/timing belt system, and a roller cam. Mounted to the front of the engine is a Moroso vacuum pump, CSR water pump, Aeromotive belt drive fuel pump, MSD crank trigger, and a Shogun alternator. I am running it on alcohol (methanol), and given the setup with the injection i am hoping that it will produce some good torque for a good ET. This engine produced 700 HP on the dyno with an alcohol carb.